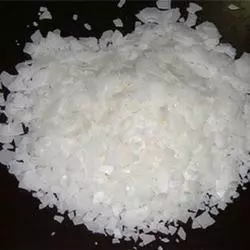

Appearance

White to a Slightly Yellow Solid Wax

Common Names

HRBD PS, Palm Wax

Packaging

As per customers request

Brief Overview

Palm stearin is the co-product of the palm oil refining process. The product undergoes a hydrogenation process to become hydrogenated palm stearin. The difference between hydrogenated and regular RBD palm stearin is the number of unsaturated chains of fatty acid molecules. Hydrogenated RBD palm stearin is known for its higher melting point than regular RBD palm stearin. At normal temperature, Hydrogenated RBD palm stearin appears white to a slightly yellow solid wax. Hydrogenated RBD palm stearin is insoluble in water, slightly soluble in gasoline, and soluble in acetone, benzol, chloroform, and alcohol.

Manufacturing Process

Hydrogenated RBD palm stearin is obtained from fractionating RBD Palm Oil to separate olein from stearin.

Dry Fractionation: This is a fully physical process. It does not require the use of any chemicals or additives so there is no yield loss and no contamination. There are no chemical changes to RBD palm oil. First, the RBD oil is heated to approximately 70ºC and homogenized to fully melt the glycerides, and then hot and homogenized oil is allowed to cool in a controlled manner. Chilled water is circulated for cooling purposes. When the oil temperature reaches the desired cooling temperature, which depends upon the quality of RBD palm oil, the cooling process is stopped. The thick crystallized mass is filtered using a drum rotary filter and membrane filter to liquid RBD palm olein and solid RBD palm stearin.

Raw Material Application

Crude palm stearin is used in the production of different types of shortening and various margarine. Crude palm stearin is the solid fraction from the fractionation of palm oil and blends with other vegetable oils to obtain suitable functional products such as margarine fats, shortenings, and vanaspati.

Coating Substitution Material Application

Hydrogenated RBD Palm Stearin is a source for producing specialty fats for coating in confectionery and the manufacturing of oleochemicals.

Hydrogenated RBD Palm Stearin is used as an essential raw material used by the shortening and margarine industries. Hydrogenated RBD palm stearin also can be used in making stearates, soap, polish cream, candles, cosmetics, and fertilizers.